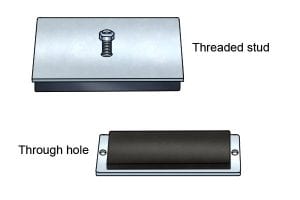

What are the parts of a threaded stud magnetic mounting pad?

What are the parts of a threaded stud magnetic mounting pad?

Check out our latest guides

A threaded magnetic mounting pad has one large rectangular magnet on its base. This magnet has only one magnetic face magnetised in the form of a multi-pole magnet.

Multi-pole magnets are magnetised in a striped pattern of alternating north and south poles e.g. north, south, north, south.

The threaded stud magnetic mounting pad requires multi-pole magnetisation due to the steel back plate preventing the magnetic field from escaping through the top of the magnetic mounting pad. Only one half of the magnetic mounting pad needs to be magnetised so that it can attach to a ferromagnetic material. The other side is used to hold the sign with the help of the threaded stud.

Rubber coating – The magnet of a threaded stud magnetic mounting pad has a rubber coating to prevent the magnet from scratching the non-ferromagnetic material it is attached to e.g. a car roof.

It also increases the amount of surface friction the magnet has.The increased surface friction helps the magnet to grip the surface of the non-ferromagnetic material.Therefore it can hold larger objects than a standard magnet such as a bar magnet.

The rubber used on the magnetic mounting pad is made of polyurethane, which is a type of polymer plastic.

The rubber coating can become indented and torn after a few years. When the magnet’s rubber coating becomes torn you can remove it with a pair of scissors and re-coat the magnet with some new rubber.

Back plate – The back plate is welded onto one of the long magnetic faces of the magnet and is used to help attach the magnet to a non-ferromagnetic material.The back plate is used to hold the threaded stud onto the magnet.

It also protects the magnet from any adverse effects from the non-ferromagnetic material it is attached to such as any bumps or scrapes which could affect the magnet’s magnetic capabilities.

The back plate on a threaded stud magnetic mounting pad is made from steel which has been coated in zinc.As magnetic mounting pads are predominantly used outdoors, the zinc coating provides corrosion resistance, whilst the steel gives the magnet added strength.

Threaded stud – A threaded stud magnetic mounting pad comes with an M6 threaded stud protruding from the magnet.This allows the magnet to attach itself to non-ferromagnetic materials with the help of a nylon insert lock nut.

A threaded stud is a rod which is threaded on both ends, which means that it has a continuous ridge around the outside in the shape of a spiral, known as the threads.The threads help attach the magnetic mounting pad to the nut as they both have corresponding grooves which interlock, holding them together securely.

Nylon insert lock nut – A nylon insert lock nut is a six sided nut with a nylon washer mounted in the top to help lock the nut into position on the threaded stud.

The nylon insert lock nut provides a more secure fit on the threaded stud than other varieties of nut. This is because the nylon washer, when attached to the threaded stud, binds itself onto the threads and provides a form of resistance against the nut being moved.

The nylon insert lock nut cannot be tightened by hand like an ordinary nut as the nylon insert binds to the threads as soon as it comes into contact with them.This means that a wrench is needed to attach the nylon insert nut to the threaded stud.

The connection between the non-ferromagnetic material (plastic sign) and the threaded stud needs to be strong to ensure that the sign does not break free in windy conditions and fall from a vehicle on a busy road.

Many nylon lock nuts only have the capacity to be used a couple of times because of the nylon inserts inability to mould itself to a range of different threads securely due to its lack of elasticity.

To test whether the nylon insert can be reused, turn the nut onto a bolt, and if the nylon provides resistance to turning using only your fingers, it can be safely used.